ILDFA is constructed entirely from marine-grade 6000-series aluminum alloy—a material proven for over 50 years in offshore platforms and industrial structures. Unlike carbon steel used in foam systems, aluminum forms a protective oxide layer that resists corrosion without coatings or frequent maintenance.

Passive by Design. Minimal Dependence by Configuration.

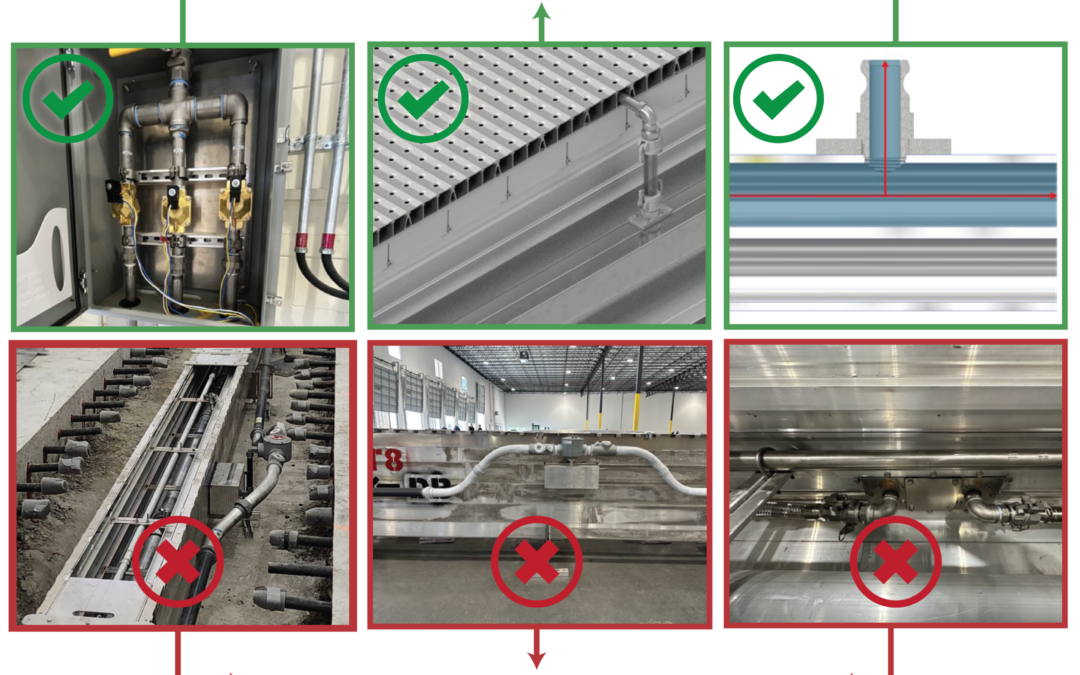

ILDFA protects by draining ignitable liquid through the floor, removing one leg of the fire triangle: fuel. Fire suppression is built into the structure itself, rather than relying on reaction-based systems.

In typical retrofit installations, a sensor-triggered, FM Approved pump and pump controller handles fuel spill removal after an event. In new builds or sites with underground drainage, reliance on mechanical or electrical components drops to nearly zero.

Legacy Foam Systems: Complexity, Corrosion, and Risk

AFFF, F3 and HEF systems rely on pumps, tanks, valves, nozzle, monitors and bladders—nearly all made from carbon steel. Despite coatings, salt air at coastal airports accelerates corrosion. In many real-world cases, significant failures begin in under 10 years.

A single mechanical fault can disable the entire foam system—or trigger an accidental discharge, causing aircraft damage or fatalities.

Even under ideal conditions, foam systems require extensive upkeep to reach their expected 25-year lifecycle. In practice, ILDFA delivers twice the lifespan with a fraction of the maintenance.

An Unmatched Warranty

ILDFA is the only hangar fire protection system backed by an unrivaled 10-year warranty, which includes inspection and maintenance support—something no foam-based system offers.

We stand behind the longevity because it’s built into the material, the design, and the performance.

Key Takeaways

- 6000-series aluminum: no coatings, no corrosion

- Passive fire protection through engineered fuel removal

- 50-year lifespan

- 10-year warranty with inspection and maintenance included