Installations

Every day a hangar is offline is a day of lost revenue. And yet, this is often overlooked when comparing ILDFA to legacy fire suppression systems. It’s not just about the capital expense — downtime during installation can have a greater financial impact than the system cost itself. That’s where Safespill makes a difference.

🔧 Built for Fast, Low-Disruption Installations

- No overhead work required — Unlike foam systems, ILDFA installs from the ground up. There’s no need to access the roof, which means aircraft don’t need to be removed for months at a time.

- Trenching operations are isolated — Since most installations require trenching, Safespill uses standard containment enclosures to control dust and protect surrounding aircraft or tooling.

🚀 Designed for Operational Flexibility

- Pre-fitted trench layouts — Trench sections are preassembled and test-fit at our Houston facility to reduce errors and accelerate fieldwork.

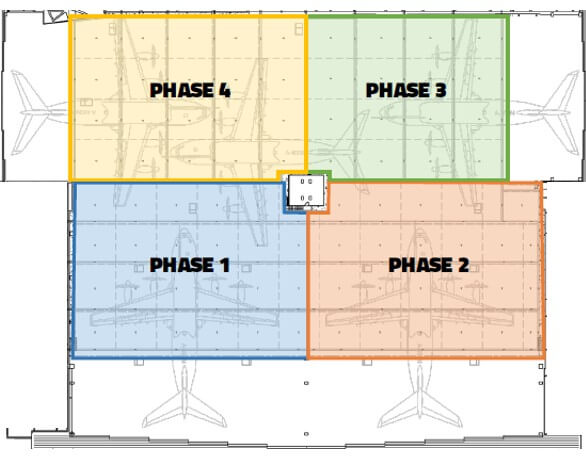

Phased installation options — For mission-critical hangars, we offer phased execution and multiple shifts to compress timelines. While we prefer clear hangars, aircraft can re-enter safely before full commissioning, as ILDFA panels are structurally sound immediately after placement.

⚙️ Light Infrastructure Requirements

- Only a 3” water line required

- Low electrical demand — ILDFA discharge pumps typically run within the capacity of existing hangar transformers, avoiding costly upgrades.

⏱️ Downtime = Lost Revenue. ILDFA Reduces Both.

When uptime matters, Safespill’s installation model delivers. We eliminate overhead retrofits, minimize operational disruption, and shorten install timelines — because that difference alone can be the deciding factor.