ILDFA Daily Operations

Fire protection is important but ensuring that daily hangar operations are not impacted and even improved for the men and women working to keep aircraft flying, is a priority at Safespill.

Tristan Mackintosh, CEO

Engineered for Every Aircraft

ILDFA can handle the weight of any aircraft, whether it’s an F-35 fighter jet or a Boeing 747. Aircraft pulled by tugs roll in and out of the hangar as if the floor has always been there, with no obstacles, restrictions, or limitations for any ground-support equipment.

Floor Impact Test

Our ILDFA floor is built for durability and safety. They are engineered to withstand daily hangar wear and tear while ensuring superior fire protection. With high impact resistance, we offer durability and easy repair to keep your operations running smoothly and safely. Discover our seamless repair process and keep your hangar fully operational with minimal downtime.

Tool & Equipment Carts

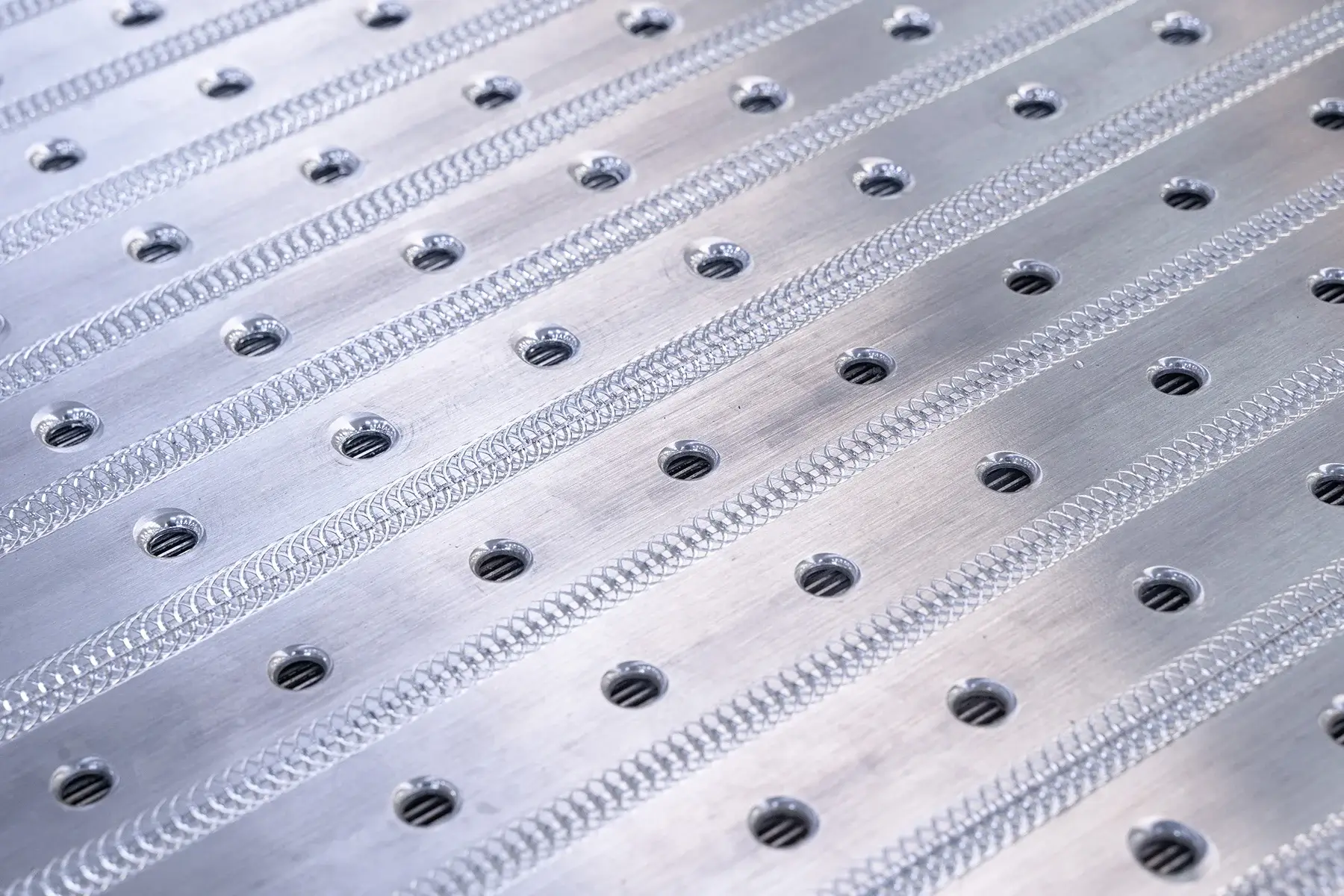

The omni directional anti slip profile is machined into the top surface with a special cutting tool ensuring that it does not wear off during the 50-year life span.

Slip Resistant Surface

The omni directional anti slip profile is machined into the top surface with a special cutting tool ensuring that it does not wear off during the 50-year life span. This anti slip profile exceeds or is equivalent to concrete or epoxy coated hangar flooring.

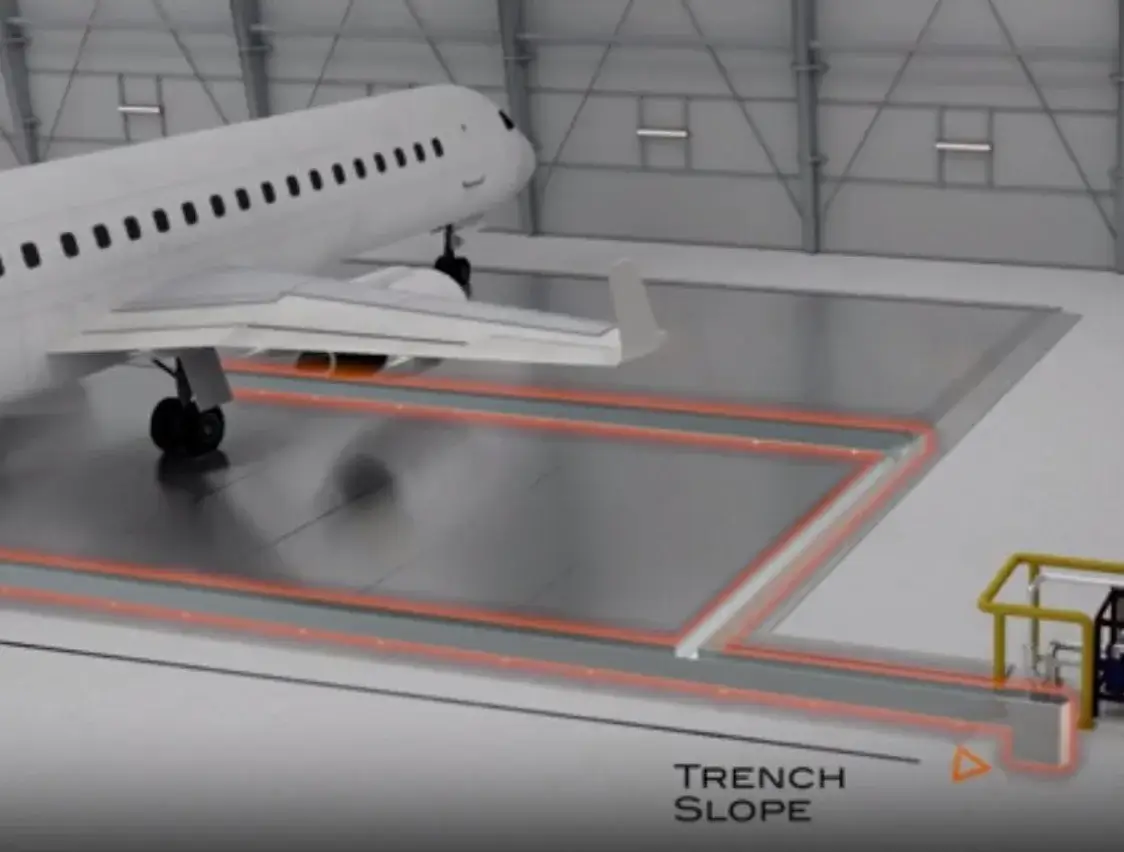

Small Spills

Having a Safespill floor or ILDFA in your hangar means no more down time in case of fuel spills. It is not recommended to ignore spill risks when performing maintenance or repairs on aircraft. However, any spilled liquid on to the top surface of ILDFA will drain into its channels and eventually make its way to the trenches that drain to an OWS, underground or above ground containment tank.

Small spills from liquids such as oils, fuel, hydraulic fluid or coffee will not trigger the fire alarm or the automatic flushing system of the floor. Automatic activation only occurs when there is a significant spill of 50 gallon (200 liter) in volume or about 5 gallon per minute (20 lpm). This is because only spills of a certain amount pose a fire risk.

Cleaning Mode

The internal geometry of the floor channels can be flushed automatically through a function called “cleaning mode” on the control panel.

When an operator determines it would be prudent to clean the insides of the floor, they activate cleaning mode on the control panel of the corresponding zone. Each zone is approximately 1,000 sqft (100 m2) so only the zone in which the spills occurred will be flushed.

Any residue of small spills on the top surface can be wiped down with a rag or a mop with a degreaser such as purple power.

Aircraft Jacks

Safespill floors have been in operation since 2021 and see daily jacking of aircraft. From F18 Fighter jets to C130 Transport Aircraft. Typical tripod jacks for any size aircraft are suitable to be used and pose no concern regarding point loads.

Specific jacking operations, such as bottle jacks or jacks with minimal contact area might require small modifications such as the use of jack plates to provide a larger contact surface. For these operations, Safespill provides jack plates free of charge to ensure daily hangar operations are not affected.

Training & User Manual

Every ILDFA installation will come with operator training and a user manual.